A brief introduction to color-coated steel

What is color coated steel?

An important innovation in steel in construction is ‘Colour Coated Steel.’ The increasing urbanisation is causing the building and construction sector to boom. This trend is giving rise to many new residential, commercial, and industrial infrastructure projects. Consequently, the architectural world is continuously researching and looking for innovations in building materials and processes. Colour-coated steel is one such innovation that is gaining a lot of momentum. With time, colour-coated steel has become a crucial material used in the building and construction sector, wherein, it is used majorly for industrial roofing and cladding, cold storage and warehouses, airports, atriums in malls, showrooms, false ceilings, lighting fixtures etc.

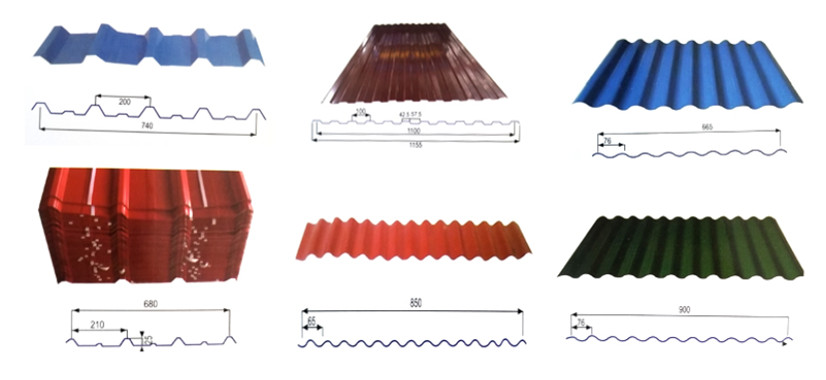

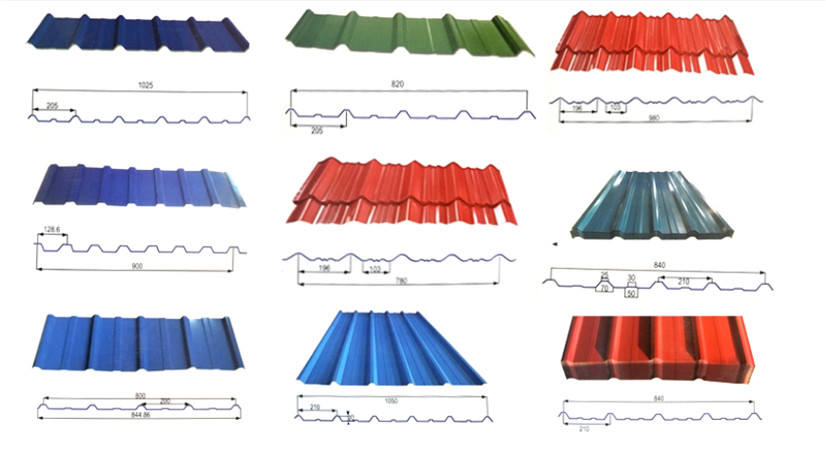

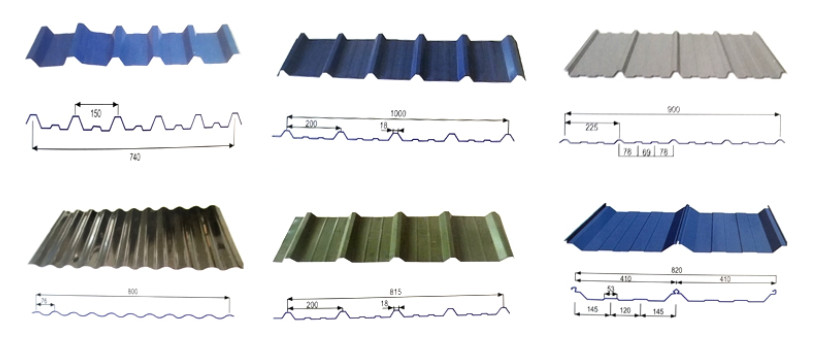

Also known as pre-painted steel, the manufacturing process of colour coated steel involves applying a decorative coating (liquid paint) to a coiled steel form. This paint coating protects the steel from atmospheric corrosion while giving it more strength and enhancing the durability. The method which imparts an aesthetic finish to the steel was started in Europe during 1940s. The usual thickness of the coating lies between 15 microns to 40 microns. The finishes achieved can be from smooth to matt and from high gloss to textured and printed for any form of steel. The sheets after the coating get the standard thickness from 0.2 mm to 1.6 mm while the width varies from 600 mm to 1600 mm.

Advantages of Colour Coated Steel

Steel has a wide range of applications; from manufacturing a small pin to automobiles, railway system, aircraft, defence materials, big engineering projects, roads, bridges, and in many other areas associated with the economic and industrial development of a country. However, the only demerit of steel is its tendency to corrode. Corrosion eats away steel, causing a significant loss to the economy of a country and sometimes leads to accidents. It has been estimated by experts that corrosion of steel costs up to 4% of the GDP of an industrialised country. Colour coated steel is an answer to this problem. The advantages of using a colour coating on steel are many. Longer life, aesthetic enhancement, recyclability – the list goes on.

Construction-Friendly Material

Colour coated steel is lightweight and high on strength. These characteristics make it extremely durable and often make way for less construction-time and easy handling and installations onsite.

A safe-bet for renovation purposes, the material’s high quality makes it extremely suitable for industrial use as well. The material can undergo intense forming operations even below – 15°C without any damage to the colour coating or the steel.

Aesthetical and Productive

Often architects and designers are left in dearth of material choices. With colour-coated steel, they are most likely to not face such a situation as it gives them a plethora of colours, shapes and textures to choose from. As already stated, the finishes can range from gloss to matt and from smooth to rough, to suit any architectural need of today’s well-informed designers. So be it an urban building or a traditional project – colour coated steel perhaps has a role everywhere.

100% Recyclable and Affordable

In a time when the world is placing a lot of emphasis on sustainability; color-coated steel can be a ‘material with a cause’ by playing a major role in building much sustainably. The low maintenance material is 100% recyclable and hence does its bit for the environment. While the sheets will protect and beautify a building for a lifetime, after getting worn out, it can be melted and converted into new steel sheet products. This also makes colour coated steel a highly economical solution, apart from just being an eco-friendly material choice.

Primary Application Areas

The increasing urbanisation is causing the building & construction sector to boom. This trend is giving rise to many new residential, commercial, and industrial infrastructure projects. Colour-coated steel has become a crucial material used in the building and construction sector, wherein, it is used majorly for industrial roofing and cladding, cold storage and warehouses, airports, atriums in malls, showrooms, false ceilings, lighting fixtures etc. The paint applied on the sheet is selected according to its resin type. Polyester coated steel still remains a favourite for the building industry. The application of colour coated steel further depends upon its type. For example, a corrugated steel sheet is used for roof boarding and shingles of villas and resorts. For building public buildings, roof coverings and walls of factories, and shop kiosks, mostly Sandwich Boards are used.

Hebei Xuanxian Trading Co., Ltd was established in 2016, work with many factories.

The company mainly exports Cold-rolled Steel Sheets, Hot-dipped Galvanized Steel Sheets(GI), Galvalume Steel Sheets(GL), Color Coated Steel Sheets(PPGI), Hot Rolled Coils, Wire Rod, Rebars and Steel Sections.

评论

发表评论